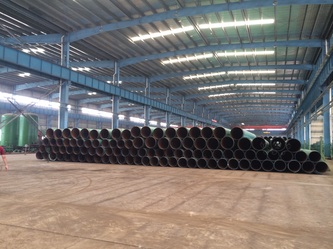

Location: China

Status: in-line; working condition

Note: The machine was originally built as 1620×25.4mm, upgraded to 1900×25.4mm. Complete mill section.

Specifications

Coil Specifications

Material: X52~X70

Coil thickness: 6~25.4 (X70≤22) mm

Coil width: 610~1800 mm

Coil I.D.:Φ610/760 mm

Coil O.D.: Φ1200-2100 mm

Coil weight: ≤45T

Product Specification

Pipe O.D.: Φ508~Φ1900 mm

Pipe Wall thickness: 6~25.4mm (X70≤22)

Pipe weight: Max 14T

Spiral angle: 40°- 80°

Length: 8-12.5m

Mill Specification

Mill Type: Front swing type; discontinuous production; Center positioning

Welding speed: 0.5~2.5 M/min

Welders: USA Lincoln DC1500/AC1200; two welders each for both ID/OD

Welding type: Double SAW welding for ID/OD

Max Pitch: 1900mm

Area: 30 M×40 M

Capacity: ≈500KW

Power source: 220/380 v

Air compressor: 0.6Mpa,0.9m3/min

Water: Flow rate: 200m3/h

Production capacity: 30k – 50k T/Y (3 shifts)

Equipment List

Coil entry

1 - Uncoiler (Coil cart)

1 - Coil end straightener

1 - Leveler

1 - Shear end welder

2 - Edge miller

5 - Edge guide roller

1 - Delivery machine

1 - Pre-bending and guide beam

1 - Front bridge

Forming and welding

1 - Forming machine (2 booms included)

1 - Inner weld mechanism

1 - Outer weld mechanism

Output

1 - V gate and support

1 - Flying cut-off cart

1 - Rear bridge

Auxiliary

1 - Buried parts

1 - Hydraulic system

1 - Electric system

Out-sourced

2 - Weld flux supply

4 - Lincoln welder

1 - Plasma cutter

1 - Cables

1 - Inline ultrasonic tester

Equipment price

Asking for price: Yang.wang@huaye.us