|

The spiral pipe mill was first built by HUAYE in 2004 and stopped production in 2011; HUAYE has done fully refurbish and major upgrade to the machine in July 2014. Now it is installed in line in HUAYE's warehouse for sale. It also has beveling machine and hydrostatic tester available together with the machine. (Watch a video)

2 Comments

Overview

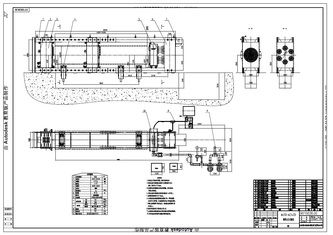

Manufacturer: Zhongyuan, China Year of Manufacture: 2008 Year of Stop: 2012 Condition: Excellent condition, installed in line Specification 1. Product specification a. Tube diameter: Φ40mm-Φ130mm b. Wall thickness: 1mm-6mm c. Production speed: 0-50m/min 2. Production flow Uncoiler – peeler - end shear and welder – guiding stand – spiral accumulator – forming mill – welder – inner and outer flash remover – cooling sink – sizing mill – turkey head – straightener – flying saw – tube discharge 3. Equipment list and major specification a. Single hydraulic uncoiler 1) Hydraulic expansion; quick coil loading; pneumatic brake 2) Coil max. weight: 3000 kg 3) Coil inner dia.: 508mm b. Peeler 1) Hydraulic cylinder driven; Pressing roller driven motor: 4 kw 2) Strip thickness: 1- 6 mm 3) Strip width: 500 mm 4) Coil outer dia.: 1600 mm 5) Feeding motor: 15 kw 6) Pressing motor: 2.2 kw 7) Flattening width: 500 mm 8) Pressing roller: 7 (thickness: 1 – 6 mm; width: 500 mm) 9) Flattening speed: 60 m/min 4. End shear and welder a. Hydraulic shear b. Width: 500mm; Thickness: 1 – 6 mm 5. Horizontal spiral accumulator a. Strip guiding roller b. Double roller feeder c. Horizontal spiral accumulator d. Strip guiding roller e. Feeding speed: ≥200m/min f. Accumulation dia.: 5.5 m g. Accumulation capacity: ≥5000kg h. Strip width: 150 – 500 mm i. Horizontal accumulator, motor: AC 22 kw j. Double roller feeding, motor: AC 18.5 kw 6. Forming mill a. Spindle size: φ110 mm; material: 40Cr b. Vertical roller size: φ65mm; material: 40Cr; Annealed and quenched c. Forming mill motor: DC 200 kw d. Forming stands: horizontal roller stands: 7; vertical roller stands: 9 e. Sizing mill: horizontal roller stands: 6; vertical roller stands: 6; f. Turkey head stands: straightening roller, 3 vertical roller, 4 vertical roller g. Welding pressing roller, three roller pressing h. Flash removal, 2 tools, pneumatic adjustment 7. Computerized flying saw a. Computerized auto control b. Saw dragging motor: 22 kw c. Sawing motor: 55 kw d. Thickness: 6mm e. Length: 4m – 10m f. Max. dia.: φ130mm g. Accuracy: ±3mm h. Saw blade: Φ800mm×Φ110mm×4mm 8. Run out table and conveyor: Driven motor 5.5KW 9. 400kw solid state HF induction welder specification a. Input power: 3P, 380V, 50HZ b. Output power: 400kw c. Output control: computerized control d. High-voltage rectifier: 40A e. High-voltage transmission: 3P, 380V, 400KVA Equipment List 1 - Uncoiler 1 - Leveler 1 - Crop shear and end welder 1 - Horizontal Spiral Accumulator 1 - Coil Entry 17 - Horizontal Roller Stands 20 - Vertical Roller Stands 1 - Press forming Roller Stands 1 - Deburring Stands 1 - Cooling sink 2 - Turks head 8 - Straightener stands 4 - Forming station 2 - Gearbox station 1 - Computerized flying saw 1 - 300KW solid state HF welder 1 - Conveyor stands 1 - Complete electric control Roller tooling 4 - Squares: 38.1×38.1, 50.8×50.8, 63.5×63.5, 80×80 8 - Rectangular: 50×30, 80×40, 80×60, 50.8×101.6, 50.8×152.4, 50.8×127, 50.8×76.2, 25.4×50.8 8 - Rounds: φ33.4, φ42.2, φ48.3, φ60.3, φ73, φ76, φ88.9, φ114.3 Thickness: 1.5 - 6mm Overview

Year new: 2009 Year stop: 2014 Builder: Taiyuan Huaye Equipment Research Institute Note: This machine has complete mechanical, hydraulic, and electrical system; inline, seldom used. Pipe Specification: O.D.: Ф610~Ф2400mm Thickness: 6~25.4mm Length: 6~12m Max. weight: 11T Machine Specification Capacity: Max. 1500T Working medium (water) Max. pressure: 5~10Mpa Transmission medium (oil) Max. pressure: 24Mpa Steady pressure time: 10~15s Main cylinder: Φ360xΦ300x800 6pcs Supercharging type: Pump 3D2-SZ-5.1/26 Power: AC380V 50HZ Control power: AC220V 50HZ Installation capacity: ~110KW Area: 18x30m Sealing type: End face sealing Equipment List 1 - Tensile beam device 1 - Fixed rack 1 - Moving rack 1 - Support for testing head 6 - Main hydraulic cylinder 1 - Hydraulic system 1 - High pressure water system 1 - Low pressure water system 1 - Hold pipe cart 1 - Electric control system 3 - Buried parts and bolts |

Machine SpecificationDetailed machine specifications will be posted in this page. Archives

May 2024

Categories

All

|

|

|

- Home

-

Products

- Spiral Welded Pipe Mill

- Pipe Beveling Machine

- Pipe Hydraulic Testers

- ERW Tube Mill

- Slitting Line

- Cut to length Line

- Conveyor

- Pipe End Expander

- Pipe Production Line Finishing Section

- Spare Part Supermarket

- Cold Roll Forming Mill

- Continuous Casting Mill

- Steel Bar Product Line

- Steel Sheet Piling Mill

- Zinc Sprayer

- Weld Pipe Ultrasonic Tester

- Used Machinery

- Service

- Projects

- News

- Download Center

- Contact Us

- Get a Quote